Cheese Making

Practical Action

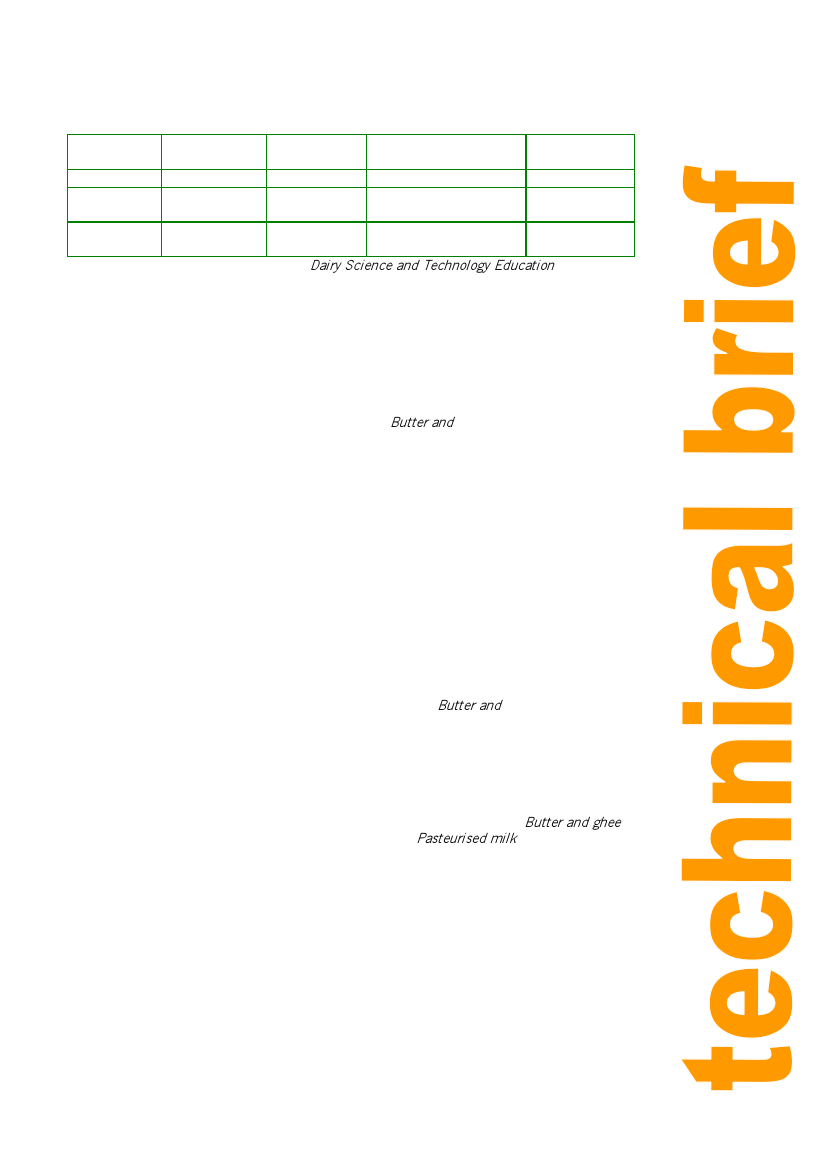

Type of

Moisture

Fat content

Texture

Shelf life

cheese

content (%)

(%)

Soft cheeses

45-75

<40 Soft, white, spreadable A few days

Semi-hard

35-45

<35 Firm, crumbly, can be A few months

cheeses

sliced

Hard cheeses

30-40

<30 Very firm, dense,

One year or

sometimes grainy

more

Table 1: Types of cheeses (Adapted from Dairy Science and Technology Education)

Methods of processing

Soft cheeses (e.g. cottage cheese, paneer, and cream cheese)

Acid is produced by lactic acid bacteria but some soft cheese may also be produced by adding acid.

Both methods coagulate milk to create pieces of semi-solid curd. The curd may be heated up to 52 oC

to inactivate the bacteria and prevent further acid development. Washing the curd before salting also

reduces the acidity. The method below describes production of curd cheese (paneer). In many

countries, traditionally produced soft cheeses have a sour taste and pronounced flavour. They are

made using fermented buttermilk (see Technical Brief: Butter and ghee), which is heated gently for

about 30 minutes until completely coagulated. It is then cooled, and the whey is drained to leave the

cheese. It is pressed into blocks and stored in brine until it is sold.

Curd cheese or paneer

1. Heat cow or buffalo milk to boiling and then reduce the heat to simmering for 5 minutes.

2. Slowly pour lime juice or lemon juice (at 1 - 1.5% by weight) into the simmering milk,

stirring it slowly using a slotted spoon.

3. Continue to stir as the milk starts to separate into curds while adding more lime/lemon

juice.

4. When the curds have formed a large mass, stop stirring and remove the pan from the

heat.

5. Allow the curds to sink to the bottom of the pan and pour off the whey (whey may be

used as a drink, made into whey cheese, or fed to animals).

6. Place the curds into a mesh sieve or colander and, without pressing, allow the liquid to

drain from the curds.

7. Cut the curds to release any extra liquid and leave it until a solid curd is formed.

Depending on the fat content of the milk (see Technical Brief: Butter and ghee) 1 litre of milk

produces about 250 g of curd cheese/paneer.

Small-curd cottage cheese

This cheese can be made with either whole milk, skimmed milk or with added cream. Adding

cream increases its smoothness and improves its flavour and texture. The method of production

for skimmed milk cottage cheese is:

1. Prepare skimmed milk using a cream separator (see Technical Brief: Butter and ghee).

2. Pasteurise the skimmed milk (see Technical Brief: Pasteurised milk).

3. Prepare the starter by adding a culture of lactic acid bacteria (either liquid or powder) to

a one litre sample of milk and incubate it at 20-25oC for 16-24 hours, or until curds

form. Keep refrigerated.

4. Pour pasteurised milk at about 20oC into a stainless steel jacketed cheese vat (Fig. 1))

with the jacket filled with hot water.

5. Add starter culture (2-3% of the weight of the batch of milk) and cover the container with

a clean cloth.

6. Do not stir the milk and allow it to stand at 20 - 25 oC for 16-24 hours. If necessary,

control the temperature of water in the outer container to maintain the temperature at 20

- 25oC.

7. When curds form, insert a knife or spatula into the curd. Gently pull the curd away from

the container side. If it breaks quickly and smoothly, it is ready to be cut.

8. Cut the curd in each direction to form approximately 0.5 cm pieces, using a knife or a

curd cutter (Fig. 2).

2